Homepage → Sustainable Storage Technologies → Hermetic Storage of Dry Grains and Other Durable Agricultural Products → Modern-Day hermetic Storage → Bunker storage of Cereal Grains (→ Old Website)

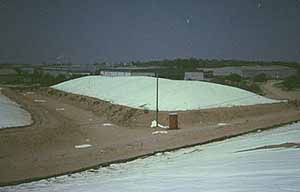

Bunker storage of Cereal Grains

Bunker storage is a sound, convenient, and inexpensive method for medium to long-term storage of grain. It has been used in different ways in countries such as Australia, USA, Turkey and Brazil. In Israel and Cyprus, bunker storage has given excellent results for long-term storage of wheat and barley (Navarro et al. 1993, Varnava et al. 1994).

The term bunker storage is used to describe large bulks of grain stored on the ground - in the open - surrounded by low retaining walls, and protected from the weather by plastic sheeting. The advantage of the Israeli version of bunker storage is that it is based on a high level of sealing using plastic liners that enclose the grain bulk and enable the grain to be stored under hermetic conditions with no need for chemical control treatments. For this purpose the specially developed liner is used to cover the top of the grain bulk while less expensive low-density polyethylene sheeting is used as a floor covering to seal the grain from beneath. Capacities of bunkers can range from smallish on-farm units of a few hundred tonnes capacity, to units containing up to 20-30 thousand tonnes each.

Situations where bunkers can provide rapid, convenient and inexpensive solutions are:

- At terminal silos when bins are filled to capacity.

- At collection sites and regional centers where incoming harvested grain is bottle- necked due to transportation problems.

- When grain is to be held on a temporary basis in anticipation of higher prices.

- For national grain reserves that require long-term storage.

- As buffer stocks for food-aid under emergency situations.

However, bunker storage is still only recommended where the harvest period coincides with the dry season of the year, since loading the grain may take many days during which time the grain is exposed to the elements. Furthermore the method is only recommended for the storage of dry grain.

Some Basic Concepts

Site Selection

Site Selection: The bunker must be located in a well-drained area where there is no danger of standing water accumulating during the rainy season. The type of bunker chosen will depend upon available funds and the time-frame for construction. The bunker floor can be made of leveled and compressed soil. Asphalt or concrete floors although they require a higher investment, are suitable, particularly when the bunker is destined for repeated use at the same site.

The position of the bunker should be such that the direction of prevailing winds is along the longitudinal axis, since this facilitates the positioning of the over-liner. Otherwise, bunker orientation should be north-south to provide uniformity of exposure of the overliner and grain-bulk to solar radiation.

Grain Handling Equipment

Grain Handling Equipment: Site preparation may be influenced by the nature of the in-loading and out-loading equipment to be used. If the bunker is to be loaded from the side by means of screw augers pneumatic conveyers or endless-belt conveyers, then side access must be sufficient for both the loading equipment, including loading hoppers, and dump trucks. If the grain bulk is in-loaded from the bunker floor itself, then the access paths on each side of the bunker will be for maintenance purpose only, but trucking access will be required to allow vehicle entry into the bunker area at the "last-in first-out" end of the bunker.

Bunker Dimensions: When the desired capacity of the bunker has been decided upon, the required dimensions can be quickly determined.

The width of the bunker is dependent upon two variables determined by the user, namely height at the centre and height at the sides, and also two variables determined by the grain, namely the angle of repose for a given grain species, and the specific gravity of the grain itself.

Height At The Centre. This is limited by the height to which the in-loader can raise the grain. Endless-belts that project the grain in an arc may reach 8 meters or more, while augers and conveyer belts may only reach a maximum of 6 meters.

Height At Sides. The higher the retaining side-walls the greater the bunker capacity per unit length. Whereas corrugated steel and concrete walls are usually 0.5 to 1 meter high, earth ramps can be raised to 2 meters. However ramps require a broad base which adds considerably to the total width of the bunker site.

Experience has shown that bunker widths of the grain-bulk greater than 25 meters are less convenient due to the quantity of plastic liner that must be drawn over the grain during the covering and uncovering process. Once the grain height at centre and sides has been decided upon, the following simple equations may be used for roughly calculating the length and width of a bunker:

L = (tanα)/(H²∂) × (t - 2H/tanα × H∂); W = 2H/tanα

∂ = density t/m³

where:

L = length of bunker in meters.

W = width in meters.

h = height of ramps in meters.

H+h = height at centre in meters.

t = storage capacity in tons.

Bunker Capacity

Decisions on bunker capacity will also determine the amount of plastic liner to be used. The larger the bunker, the smaller the surface area per unit volume of grain, and the smaller the capital investment per tonne of grain stored. However, this calculation should be weighed against the convenience of building a number of smaller bunkers with the inherent convenience of handling and managing the smaller grain bulks.

Bunker Construction

Earthen Bunker

Earthen Bunkers: If the bunker construction is to be based solely on earth moving equipment (graders, bulldozers, tractors or other earth moving equipment), the bunker floor should be leveled and earth removed in this process should be used to form the retaining ramps along one end and along the two sides of the bunker. Soil types that permit compacting will enable ramp construction to heights of one to two meters. Ramp cross section should be trapezoidal, (see figure). For a 2 meter high ramp the base should be about 8 meters wide and the top of the ramp 3-4 meters wide. The closed end-ramp should be shaped to the same dimensions as the side ramps to form a radius equal to half the distance between the parallel side walls. This semi-circular end-ramp eliminates the need to fill the corners with grain.

Semi-permanent or Permanent Bunker Sites: For multiple usage, concrete walls (either modular or continuous) or galvanized iron or steel retaining walls attached to posts may be used, while the floor may be lined with concrete or asphalt.

Drainage:Proper drainage of run-off water from the overliner is essential. For this reason surrounding ground should be lower than the bunker floor and sloping away from the bunker. Where earth ramps are constructed, earth from outside the bunker is used to form the ramps and by so doing the level outside the ramps is lowered. The access and maintenance paths around the bunker can then be graded to ensure run-off. The bunker floor should be graded from the closed end to the open end with a slope of at least 3%.

The Bunker UnderlinerWaterproof plastic sheeting should be laid across the floor and over the retaining walls to prevent moisture migration and gas exchange between the grain bulk and the ground. We advise use of 200 to 250 micron polyethylene sheeting laid progressively as loading advances, with an overlap of at least 15 cm "tile fashion" down the angle of slope. Each additional sheet should be laid as described above and sealed with tape. An allowance of at least 2 meters of sheeting beyond the retaining walls should be given to enable the underliner to be sealed with the overliner. Care should be taken to avoid damage to the underliner during loading, and walking or driving over the liner should be minimized to prevent tears The underliner should be discarded and replaced after each storage period.

Loading:Grain for bunker storage should be at safe moisture contents. We would recommend maximum safe moisture contents for common cereal grains such as wheat: 12%, and corn: 12.5%. Whether loading is by screw conveyer, belt conveyer, sucker-blowers, or spinning belt propulsion the main objective is to load from the center point of the bunker, so as to fill the sides to a uniform height as the grain bulk assumes its natural angle of slope. At the sides the grain should be loaded to about 10 cm below the top ridge to allow for settling during the covering process. Uniformity of loading with evenly angled sides is also important to ensure that after the overliner is positioned, there will be no valleys or craters that fill with rainwater and form standing pools. For loading systems where the grain is propelled through the air, prevailing wind may cause drift and this should be taken into account. For augers, a directional chute attached to the outlet point can be used to provide uniformity of loading. As the bunker fills, the loading equipment should be gradually pulled towards the open end. If the grain is destined for prolonged storage (16 months to 2 years or more) we would recommend that the peak be leveled off to provide a 2 to 4 meter flat ridge along the top. Although this reduces the total storage capacity of the bunker, it has been shown (Varnava et. al 1994) that this almost eliminates the problem of moisture migration to the bunker peak, that has been experienced during the spring and autumn seasons when strong temperature gradients are set up within the grain bulk. A final hand-trimming of the bunker stack to fill depressions is normally required before the overliner is positioned.

The bunker overliner is supplied as pre-welded sheets

Covering the Bunker: The bunker overliner is supplied as pre-welded sheets in convenient dimensions that minimize the need for in-field welding. The pre-welded sheets are supplied folded in zigzag fashion and rolled onto rollers, so that they can be drawn over the grain surface from one side of the bunker to the other, using an attachment rope and winch and then unfolded. The bunker need not be completely full before covering commences, and it is even advisable to cover the bunker progressively in order to protect the bulk from sudden storms (though as mentioned previously bunker storage is best suited to areas where the harvest period coincides with the dry season). The junctions between the pre-welded sheets are then welded in situ to form a complete surface cover. The hot-air welding method employed by our technicians can be transferred to local technical staff to enable this procedure to be carried out in future loadings by local personnel. Should small repairs of tears or holes be required, this can be done with patching material and a solvent glue supplied by the manufacturer. Before sealing, the welded over-liner should be weighed down around its periphery using sand bags to prevent wind from shifting its position.

Sealing

Bunkers With Earthen Ramps

Bunkers With Earthen Ramps: For these bunkers, the overliner should also project about 2 meters from the edge of the grain bulk. To seal the overliner and underliner, the most convenient method is to use a trencher to dig a trench 50 cm deep and 30cm wide and about 1 meter from the inner edge, along the top of the earth ramp. The projecting edges of the over- and under-liners are then rolled together and buried inside the trench. After the liners have been sealed together, a surrounding apron 3 to 4 meters wide should be welded to the overliner at its junction with the ramp. This apron extends over the earth ramp and protects it from damage by water run-off during the rainy season.

Bunkers With Retaining Walls: To prevent chafing or tearing of the liners at the point of contact with the retaining walls, it may be advisable to glue a layer of 2-3 cm thick strips of insulation material formed from synthetic fiber along the top of the wall. To seal the liners together, the over- and underliner are pulled over the retaining walls and then rolled together and weighted down with sand-snakes.

Monitoring procedures

Screw-cap sampling ports can be welded at convenient distances along the apex of the bunker. These may be used to monitor for gas concentrations, installation of thermocouple cables for temperature monitoring, and removal of grain for sampling. Alternatively for spot sampling the liner may be cut open, the sample removed and a patch placed over the liner.

Unloading The Bunker

The top cover should be progressively removed and folded. It should be stored for re-use in a rodent free environment, preferably on pallets. The seams between sheets should be cut with a sharp Stanley type knife. Careful removal and storage of the overliner sections will enable re-use for many times. Grain removal starts at the lower end. A mobile auger with cross sweep is suitable, as also are front-end loaders which can remove the grain rapidly from within the bunker area. Remaining grain can be removed using vacu-vators (sucker-blowers) or brooms and shovels. It is possible to reseal a bunker after partial unloading. However, because the hermetic seal is broken during unloading, the hermetic storage principle is no longer valid, and repeated partial unloadings is not a recommended procedure.

Important: The plastic may be damaged by mechanical punctures and by contact with certain chemicals. Avoid contact with herbicides, oil products or oil based formulations as these may have a deleterious effect on quality of the membrane.

Security Measures

The bunker over-liner does not provide protection from pilfering. Also if animals are free roaming in the vicinity, fencing should be provided to protect the bunker.

Our References

Navarro, S., Donahaye, E. Kashanchi, Y., Pisarev, V. and Bulbul, O.

(1984) Airtight storage of wheat in a PVC covered bunker. In: Controlled Atmosphere and Fumigation in Grain Storages, (Edited by Ripp, B.E. et al.), pp. 601-614, Elsevier Sci. Publ. Co., Amsterdam. Holland.

Abstract and Full Paper Download.

Navarro, S. Varnava, A. and Donahaye, E.

(1994) Preservation of grain in hermetically sealed plastic liners with particular reference to storage of barley in Cyprus Proc. Int. Conf. Controlled Atmosphere and Fumigation in Grain Storages Winnipeg, Canada, June 1992. pp 223-234. Caspit Press Ltd., Jerusalem.

Abstract and Full Paper Download.

Varnava, A., Navarro, S. and Donahaye, E.

(1995). Long-term hermetic storage of barley in PVC covered concrete platforms under Mediterranean conditions. Postharvest Biol. & Technol. 6: 177-186.

Abstract and Full Paper Download.